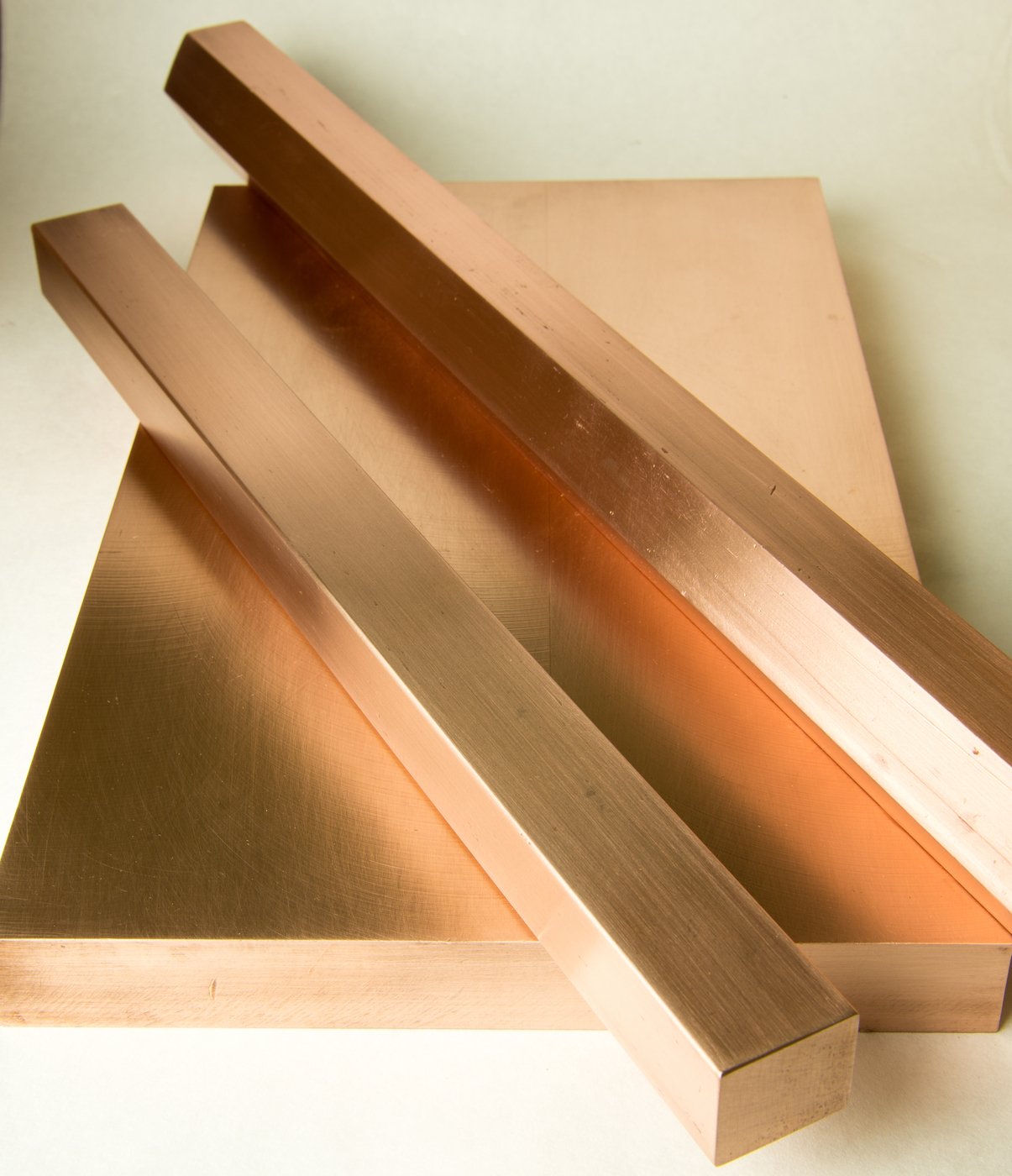

COPPER ZIRCONIUM

Copper Zirconium C15000, RWMA Class 1, AWS J1.3

Copper Zirconium is an excellent resistance welding material with very high softening temperatures. A small addition of zirconium to copper improves resistance to softening and resists deformation at high temperatures where normal copper would soften rapidly. Copper Zirconium is used as an RWMA Class 1 electrode material to minimize sticking when resistance spot welding galvanized/coated materials.

|

Chemical Compositions of RWMA Materials Group A - Copper Base Alloys |

||||

|

RWMA Class |

UNS Number |

Description |

Cu + Zr |

Zr |

|

1 |

C15000 |

Copper Zirconium |

99.90% min. |

0.10 – 0.20% |

Cu: Copper

Zr: Zirconium

Typical usages of RWMA Class 1 Copper Alloy: C15000 is recommended for spot welding of coated steels and high conductivity materials, excluding copper and silver.

|

GENERAL USES OF C15000 |

|

||

|

Axial Conductors |

Back-up Electrodes |

Bushings |

Caps & Shanks |

|

Casting Wheels |

Centrifugal Casting Molds |

Circuit Breaker Parts |

Collector Connector |

|

Collector Housing |

Connector Bar |

Connectors |

Connection Lead Bar |

|

Continuous Casting Molds |

Cross Wire Welding Electrodes & Components |

Damper Ring/Fingers |

Dies & Fixtures |

|

Electrode Holders & Adaptors |

Electrical & Mechanical Power Components |

End Rings & Rotor Bar |

Flash & Butt Welding Dies |

|

Flexible Connector |

Joining Components |

Lead Conductor Bar |

Neutral Bus Bar |

|

Nut & Stud Welding Electrodes |

Power Generation Products |

Power Semiconductor Bases |

Resistance Welding Electrodes |

|

Rotor Coil Bar |

Seam Weld Wheels |

Series Loop Segment |

Slip Rings |

|

Shafts |

Slot Wedge |

Snap Rings |

Special Nipple |

|

Spot Welding Electrodes |

Terminal Box Connectors |

Transmission Devices |

Threaded Electrodes |

|

Water Clip |

Welding Arms |

Welding Blocks |

Welding Connectors |

|

Welding Platens |

|

|

|

| Item Name: | Copper Zirconium Alloy C15000 |

| RWMA (Resistance Welding Manufacturing Alliance) Class: | Class 1 |

| Principal Element: | Cu, Zr |

| Minimum Hardness Rockwell (up to 1" dia.): | HRB 65 |

| Minimum Electrical Conductivity (% IACS): | 80 |

| Metal Stock Availability: | Stocked in mill form or precision cut to your specifications. |

| Shape: | Bar Hexagon Octagon Plate Rectangle Round Special Square |

| Length for Round, Hexagon, Square, Octagon, Rectangle, Special Shapes: | All sizes in standard lengths up to 12 ft Special Sizes |

| Diameter for Round, Hexagon, Square, Octagon, Rectangle, Special Shapes: | 1/8 to 8 1/8 in Special Sizes |

| Thickness for Plate: | 1/8 to 8 in Special Sizes |

Quality Assurance

Quality Policy: Cadi Company Inc. is dedicated to world-class excellence. Our commitment is to continually achieve the highest standards required to meet our customer’s needs. Cadi is committed to a policy of continuous improvement within all areas of the organization through customer communication, by means of quality planning and review, as well as employee training and participation to achieve the Cadi commitment goal of 100% in quality, effectiveness, and customer satisfaction.

Quality Objectives: Cadi Company, Inc. is committed to the development and implementation of the ISO Quality Management System. We pledge that through the efforts of all our employees working together as a team, we will continually strive to be a leader (in our markets) in satisfying our customers’ needs with regard to service, performance, and competitive pricing. Cadi shall maintain global and domestic sources to provide quality products as required by our customers. Cadi will provide our customers with the highest level of satisfaction by achieving the goal of 100% in the areas of product quality and on-time delivery performance.

Cadi Company is committed to providing goods and services that meet or exceed our customer’s requirements and expectations. It is our firm belief that this dedication to the highest standards is the cornerstone of our existence.

- We have the equipment and processes to guarantee the quality of the products we manufacture.

- We continually upgrade our equipment and have ongoing training company-wide.

- Each order undergoes stringent Quality Assurance Processes to assure accuracy and precision to the client’s specifications and is verified throughout the manufacturing cycle with scheduled quality assurance audits.

- All material is subject to detailed physical tests where microstructures, tensile, yield strength, U.T. testing, eddy current conductivity, elongation, and hardness are measured and reported.

- Climate-controlled inspection facility.

- We have a Metallurgical Engineer on-site for any technical questions.

To ensure Cadi follows rigorous quality and procedural protocols we are ISO 9001:2015 Certified and have been for over 18 years.

| ISO Certification: | 9001:2015 (Registration # 10002745 QM15 Valid until 2027-08-21) |

| Reports: | Certification of Compliance Chemical Analysis Final Inspection Material Test Reports |

| Mechanical and Physical Testing: | Elongation Grain Size Hardness Tensile Yield |

| Nondestructive Testing: | Chemical Analysis Conductivity Liquid Penetrant Ultrasonic X-Ray |

| Alloy Applications Cross Reference Chart | C15000 | C18150 | C18000 | C18200 | C17510 | C17200 | C15760 |

| Axial Conductors | X | - | - | - | - | - | - |

| Back-up Electrodes | X | X | X | X | X | X | X |

| Bushings | X | X | X | X | X | - | - |

| Caps & Shank | X | X | X | X | X | X | X |

| Casting Wheels | X | X | - | X | - | - | - |

| Casting Wheels and Dam Blocks | - | - | X | - | X | X | - |

| Centrifugal Casting Mold | X | X | X | X | - | - | - |

| Circuit Breaker Parts | X | X | - | X | - | - | X |

| Collector Connector | X | X | - | X | - | - | - |

| Collector Housing | X | X | - | X | - | - | - |

| Connector Bar | X | X | - | X | - | - | - |

| Connectors | X | X | X | X | X | - | X |

| Connection Lead Bar | X | X | - | X | - | - | - |

| Continuous Casting Molds | X | X | X | X | X | X | - |

| Cross Wire Welding Electrodes & Components | X | X | X | X | X | X | X |

| Damper Ring/Finger | X | X | X | X | - | - | - |

| Dies & Fixtures | X | X | X | X | X | X | - |

| Die Casting Pistons | - | - | X | - | X | X | - |

| Die Casting Plunger Tips | - | - | X | - | X | X | - |

| Electrode Holders & Adaptors | X | X | X | X | X | X | - |

| Electrical & Mechanical Power Components | X | X | X | X | X | X | X |

| Flash & Butt Welding Dies | X | X | X | X | X | X | X |

| Flexible Connector | X | X | - | X | - | - | - |

| Heat Flux Components | X | X | X | X | X | - | X |

| Injection Blow Molds & Dies | - | X | X | X | X | X | - |

| Joining Components | X | - | X | - | X | X | X |

| Lead Conductor Bar | X | X | - | X | - | - | - |

| Motor End Rings | X | X | X | X | X | - | - |

| Neutral Bus Bar | X | X | - | X | - | - | - |

| Non-Sparking Applications | - | X | X | X | X | X | - |

| Nut & Stud Welding Electrodes | X | X | X | X | X | X | - |

| Performance Engine Components | - | - | X | - | X | X | - |

| Permanent Molds | - | - | X | - | X | X | X |

| Power Generation Products | X | X | X | X | - | - | - |

| Power Semiconductor Bases | X | X | - | X | - | - | - |

| Resistance Welding Electrodes | X | X | X | X | X | X | - |

| Rotor Coil Bar | X | X | - | X | - | - | - |

| Seam Weld Wheels | X | X | X | X | X | X | - |

| Series Loop Segment | X | X | - | X | - | - | - |

| Shafts | X | X | X | X | X | X | - |

| Slip Rings | X | X | - | X | - | - | - |

| Slot Wedge | X | X | X | X | - | - | - |

| Snap Rings | X | X | - | X | - | - | - |

| Special Nipple | X | X | - | X | - | - | - |

| Sputtering Target Backing Plate | X | X | X | ||||

| Terminal Box Connectors | X | X | - | X | - | - | - |

| Threaded Electrodes | X | X | X | X | X | X | - |

| Transmission Devices | X | X | - | X | - | - | X |

| Water Clip | X | X | - | X | - | - | - |

| Wear Plates | - | - | - | - | - | X | - |

| Welding Arms | X | X | X | X | X | X | - |

| Welding Blocks | X | - | X | - | X | X | - |

| Welding Connectors | X | X | X | X | X | X | - |

| Welding Platens | X | X | X | X | X | X | - |

NOTE: C15000 Copper Zirconium and C18150 Copper Chromium Zirconium are both good replacements for C16200 Copper Cadmium. C15000 Copper Zirconium is a good replacement because of its excellent thermal and electrical conductivity while offering moderate strength. C15000 strength properties are developed through cold working (similar to C16200) whereas C18150 strength properties are developed primarily from heat treating (precipitation hardening), which is an advantage for large parts.

Other References For C15000: Class 1 Copper, RWMA Class 1 Copper, Copper Zirconium Supplier Manufacturer Distributor, CuZu Copper, UNS C15000, CDA C15000, Amzirc C15000, and Amzirc.